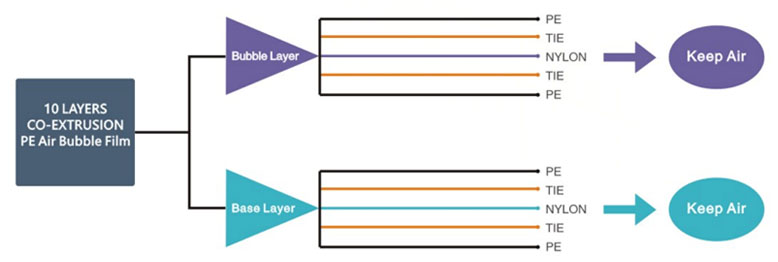

Description

Co-extrusion bubble wrap machine consists of a main extruding system, a forming

system, a winding system and an electric control system. Main extruding system

controls PE layer, EVA layer and nylon layer separately via 6 single screws.

Thickness and flow can be separately controlled in each layer, ensuring better

product quality.

Application

Co-extrusion bubble films, which are primarily used in high-end products such

as automobile parts packaging, high-end cigarette and alcohol packaging,

precision instrument packaging and packaging of ceramics, glass and optical

instruments, bears more pressure than regular bubble films. Because of its

shock-proof, moisture-proof and wear-proof ability, co-extrusion bubble films

quickly made its way to becoming the most popular packaging material.

Features

1. Our co-extrusion bubble wrap machine has very high production capacity, with

a maximum speed of 50 meters per minute.

2. This bubble wrap machine has very good quality. Ztech's forming cylinder

mold is designed with an up-to-date vacuum system, with special steel sheets to

prevent wearing, and with a dual pipe cooling system to realize better and more

even cooling effect. Ztech's unique T-die design is of vital importance to

producing high quality bubble films. Precise T-die materials makes products

even in thickness, realizing an easier operation flow and prevents glue

leakage. Ztech's screw design makes recycled materials 100% usable, ensuring

that bubble are even in thickness and better in quality.

3. This bubble wrap machine comes with a strict safety system. Emergency stop

button can stop the entire machine, including circuits, extruders and cylinder

of roller. Protective barriers are installed on all important parts, all

actions halt automatically to prevent damage whenever protective barriers are

opened.

4. This bubble wrap machine has very good composite effect. Up-to-date

technology ensures that its composite effect stands out

Technical Parameters

Model: Nylon coextrusion bubble film machine

|

Layer |

3 |

|

Raw materials |

Low density polyethylene / linear low density polyethylene / recycled material/HDPE |

|

Maximum width (mm) |

2030 |

|

Effective width after trimming (mm) |

2000 |

|

Speed (m/hr) |

800m/hr-2000m/hr |

|

Production Capacity (kg/hr) |

158kg/hr-248kg/hr |

|

Range of film thickness (g/m2) |

2 layers: 25g/sm-300g/sm |

|

Bubble Layer Extruder screw diameter (mm) |

PE layer:Φ90mm EVA layer:Φ 45mm NYLON layer:Φ 35mm |

|

Base Layer Extruder screw diameter (mm) |

PE layer:Φ90mm EVA layer:Φ 45mm NYLON layer:Φ 35mm |

|

3rd Layer Extruder screw diameter (mm) |

Φ75mm |

|

Screw length-diameter ratio |

30 : 1 |

|

Temperature control region |

28 |

|

Power of Bubble Layer motor (kW) |

PE layer:45Kw EVA layer:11Kw NYLON layer:11Kw |

|

Power of Base Layer motor (kW) |

PE layer:37Kw EVA layer:11Kw NYLON layer:11Kw |

|

Power of 3rd Layer Extruder motor (kW) |

22kw |

|

Power of vacuum pump (kW) |

3 |

|

Maximum rolling diameter (mm) |

Φ1000mm (Can be customized upon requested) |

|

Power Supply |

380V,50HZ,3 PHASES(Can be customized according to different countries) |

|

Total power (kW) |

210 |

|

Heating power (kW) |

122 |

|

Effective power (kW) |

63 |

|

Weight (kg) |

10200 |

Selectable Parts

Customers support

Ztech supplies bubble wrap machines to clients in more than 50 countries or regions in the world, including America, Canada, Russia, Japan, Australia ,New Zealand, Brazil, Poland, Spain, Portugal, UK, Greece, Ukraine, Mexico etc.

Address : No.4 Yangda Road, Xiyong Area, Lunjiao Town, Shunde District, Foshan City, Guangdong Province, China (P.S.code:528308)?

Tel : 0757-22817002

Website : m.swipkitchenware.com

copyright : ZTECH

Powered by : sowho.cn